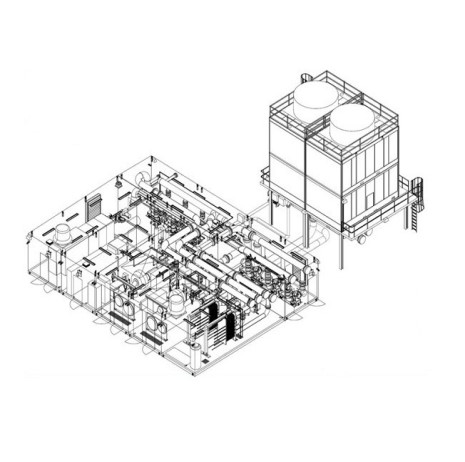

A large pharmaceutical company in New Jersey was looking to evaluate and improve the performance of their new, fully-automated chiller plant. Enica started by collecting the appropriate data to establish baseline operation, identify the operational flaws, and develop energy conservation measures.

The next step was to download the automation system programming in order to evaluate and modify it. The code was custom edited to correct operational issues and improve energy efficiency. Enica worked with the BAS contractor to implement Enica’s new code, line-by-line, to ensure that there were no interruptions to plant operations during the process.

Enica was able to reduce the plant’s annual energy consumption by 25%. There was also a substantial drop in operational issues, improving the reliability of the plant and allowing it to run without requiring virtually any operator input.