Q: What Does Success Look Like for Your Air Change and Room Pressurization Program?

A: Achieve Environmental Health and Safety Goals

For the past few years, indoor environmental control and indoor air quality (IAQ) have been important topics in the broader building industry, but these topics are familiar to the healthcare industry, where proper indoor environmental control is necessary. The pandemic and post-pandemic eras have shed new light on issues like IAQ and building health. This has increased public awareness across all domains, but the topic is significantly amplified in patient healthcare environments.

The increased social awareness and attention to these topics make it imperative that hospitals and healthcare facilities prioritize indoor environmental control. In this blog, we’ll provide insights into how hospital facilities managers, owners, and operators can leverage an efficient air pressurization control program to improve environmental health and safety, successfully achieve compliance, and ultimately set up facilities for success.

Silos, Limitations, and Issues with Compliance Air Balancing

Segmenting teams create a siloed approach to your air change and pressurization control program, leaving you, as the facilities manager, suck in the middle between an entity that measures the air readings and a separate entity that makes adjustments to your building automation system for airflow control. We’ve seen some situations where facilities managers need to deploy at least three independent entities:

- An air balancer for air change and air pressurization readings

- A building management system (BMS) or building automation controls vendor for flow control manipulation

- A facilities operations staff or in-house team member to orchestrate the process

A Holistic Approach to Building Automation and Airflow Control

Enica’s National Environmental Balancing Bureau (NEBB) certified compliance air change and room pressurization team leverages our building automation system expertise. Our team combines the three-segmented groups listed above under one section that can achieve air change and room pressurization compliance. We understand that generating an airflow measurement report is merely a fraction of the battle.

The goal is to get your facility into a position of confidence where the majority of your critical environments operate in compliance. Air change and room compliance is essential to setting facilities managers up for success with The Joint Commission and any published environmental health and safety standards and guidelines.

Streamlined Reporting and Trusted Results

Enica has revolutionized the concept of “near-real-time-reporting.” We’ve created a streamlined style of reporting supported by an intuitive database for facilities managers to see air changes, pressurization readings, and other BMS or system manipulations as they happen.

Quality assurance reviews happen immediately after field data entry, which allows facilities managers to customize and publish executive summary reports or individual room-by-room reports on demand. The reporting system is automated and flexible, so managers and owners can quickly and efficiently track remedial action efforts in one place.

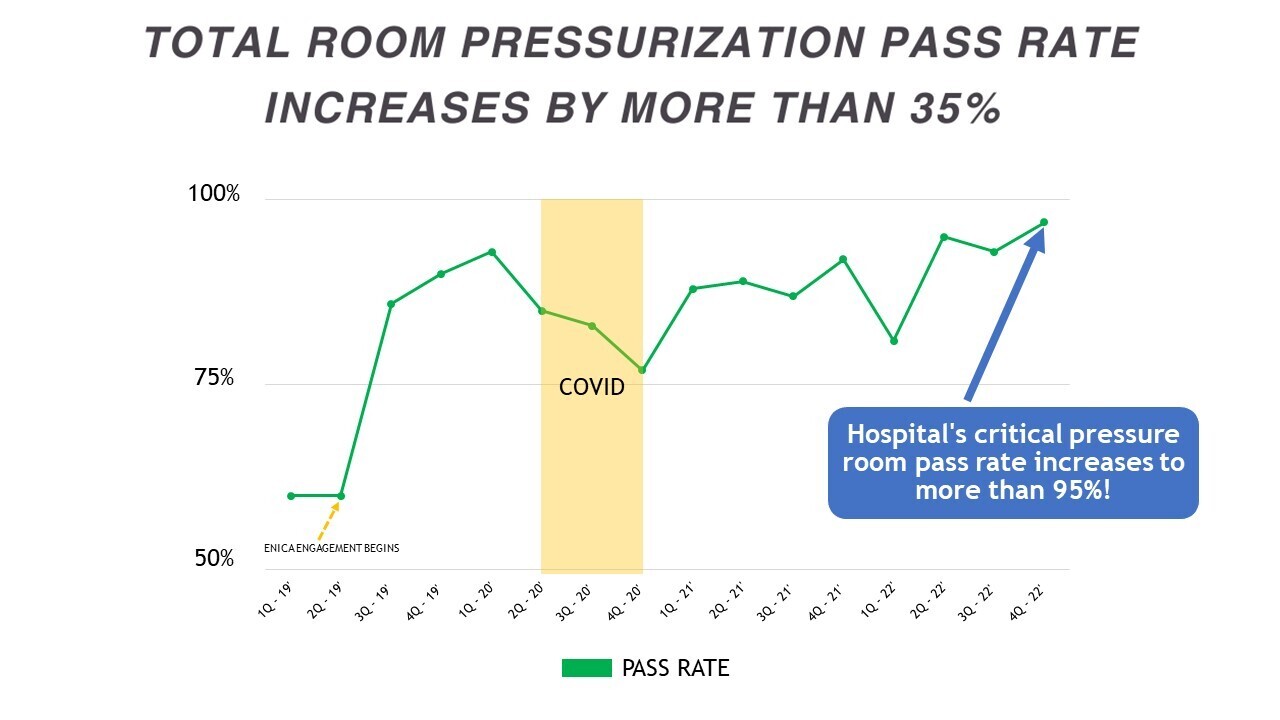

Proven Results

A large healthcare facility recently deployed the Enica approach across their facility with great success, significantly improving their room pressurization pass rate. Our team was able to move progressively through the facility during nights or after hours when spaces were available to identify and remediate issues. The team was able to achieve 93% compliance across all rooms.

The Game Changer: System Optimization

In addition to setting up facilities managers for better compliance reviews, Enica’s air change and pressurization program often inherently results in more optimized and more energy-efficient system operations. Many projects result in better air delivery, tighter sealed ductwork, and less air leakage from rooms.

Ultimately, the air change and room pressurization control process has pros and cons in both the energy credit and debits columns. But generally speaking, being able to control your facility better results in more optimized, reliable, and confident operation, which is more economical overall.

By combining disparate skillsets under one specialized team and leveraging software for real-time reporting, Enica is disrupting the industry at a time when indoor environmental control is high on everyone’s radar. If you have critical systems, operating suites, isolation rooms, or other areas of your healthcare facilities that are a nagging concern, Enica is here to help set up you and your facility for success.

Reach out to our experts today to discuss your hospital’s unique needs >>